Apples

Blueberries

Cherries

Citrus

Grapes

Pomegranates

Strawberries

Read the article for details: https://nexusnewsfeed.com/article/food-cooking/seven-fruits-that-may-help-lower-cancer-risk/

Tom's Blog on Life and Livingness

Apples

Blueberries

Cherries

Citrus

Grapes

Pomegranates

Strawberries

Read the article for details: https://nexusnewsfeed.com/article/food-cooking/seven-fruits-that-may-help-lower-cancer-risk/

THE CLIMATE REPORT FROM HELL

At the end of July, the U.S. Department of Energy published a report that sent the entire American climate-industrial complex into a frenzy. Titled “A Critical Review of the Impact of Greenhouse Gases on the U.S. Climate”, the report immediately provoked a fierce reaction from the climate movement’s mouthpiece, *The New York Times*: “The report is written by climate skeptics who undermine scientific consensus, an attack on all serious climate research. The five scientists behind the Department of Energy’s report falsify data and draw conclusions far removed from the UN’s climate warnings, which form the basis for the green transition.” This was followed by over 60,000 protest letters to the Department of Energy and a barrage of lawsuits from institutions like the Environmental Defense Fund and the Union of Concerned Scientists.

The report, authored by five prominent scientists, including former Obama administration Department of Energy research director Steven Koonin and Professor Judith Curry, is not a malicious attack on the UN’s climate scenarios but a sober, factual, and compelling presentation of 200 years of concrete measurements and documented observations of climate development in the U.S. To understand the outrage and fury of the American climate mafia, it’s crucial to note the movement’s fundamental creed, as outlined in a 2008 report by the U.S. Environmental Protection Agency (EPA), which declares that human-made greenhouse gases, particularly CO2, are dangerous to human life and health, recommending that emissions be reduced as much as possible.

However, the current Department of Energy report clarifies that elevated CO2 levels (which no one disputes) have increased plant growth and Earth’s green areas, accelerating productivity and crop yields in agriculture. It further concludes that existing climate models are burdened by unrealistic catastrophe scenarios, rendering them unreliable as forecasting tools. Thus, climate researchers exaggerate long-term trends in extreme weather in the U.S. The frequency and intensity of tornadoes, floods, and droughts have not increased abnormally. The climate movement and media wrongly and without evidence attribute extreme weather to increased atmospheric CO2. The report does not deny that CO2 emissions may affect the climate but calls for scientific documentation of their interaction with the sun’s influence on Earth, cloud formation, and movements in wind and ocean currents, which have been the dominant climate drivers for billions of years.

The rage and hysteria surrounding the climate report have reached new heights because the throne of the climate activists’ doomsday empire is beginning to wobble. More and more scientific heavyweights are emerging as doomsday deniers, most recently Nobel Prize-winning physicist John Clauser, who has presented analyses concluding that “there is no climate crisis.” The climate-industrial complex, encompassing universities, media, and nearly all politicians, has responded by academically exiling Professor Clauser, who is now barred from speaking, lecturing, or debating in Western democracies. The same applies to the report’s co-author, Dr. Judith Curry, who has been bullied out of her professorship at the Georgia Institute of Technology. She has dared to present facts showing that deaths from extreme weather have decreased more than 100-fold and that humanity has experienced cultural and technological flourishing during Earth’s warm periods. Since 1850, the planet has warmed by 1.3 degrees Celsius, which has only had positive effects on human life and welfare. Professor Curry is not afraid to state that climate science no longer rests on serious research but has become pseudoscience, driven by careerism, funding, income, and tenure in academia. If you align with the doomsday narrative, you get a career and success. If not, you’re finished. Curry calls for open and unbiased scientific debate: “Disagreement is the salt of science,” she says.

With the current Department of Energy climate report, she has sparked that debate, but it has been met only with hatred, condemnation, and rejection. The sober and unbiased climate debate is struggling, not least because climate activists sense that voters in Western democracies are beginning to realize they’ve been misled and deceived by the golden promises of the green transition.

Europe is being driven into decline compared to the U.S., China, and India as a result of the green assault on our societies. Today, Germany and Spain derive about 55 percent of their energy from wind and solar. Germany has shut down its nuclear power plants, and Spain is in the process of doing the same. This trend is evident across the EU. The result is energy shortages, sky-high energy prices, and massive imports from Russia, which can finance its entire Ukraine campaign with the influx of energy euros.

In 2008, the economies of the Eurozone and the U.S. were at similar levels. Today, U.S. GDP per capita is nearly double that of Europe. While the U.S. extracted shale gas and invested in innovation and growth, Europe chose to tax itself into an economic slowdown. Europe’s technological elite companies are Siemens, Vestas, and Ørsted. The U.S. has Apple, Google, Microsoft, Amazon, Nvidia, and Open AI. The four largest U.S. companies are worth more than all 402 companies on the MSCI Europe stock index combined.

When European politicians twenty years ago wholeheartedly embraced Al Gore’s doomsday narrative, predicting six-meter sea level rises, no more snow or ice, and famine, it was because the doomsday story offered new opportunities to control the electorate. If a better climate depends on individual citizens’ diets, clothing, transportation patterns, and energy consumption, then it must also be true that a government for the sake of the climate can micromanage its citizens’ behavior from cradle to grave. And so they do. The commitment to the doomsday doctrine has given politicians their wildest dream on a silver platter: the nanny state.

We need a popular uprising to restore common sense, healthy skepticism, and judgment in the climate debate. The first politicians are beginning to slip out the climate backdoor. We must hope that the courageous and sober report from the U.S. Department of Energy motivates many more to follow suit. We need to turn the climate narrative around. Otherwise, only poverty and hardship await us.

By Asker Aamund.com 20/08/25 (translated from Danish)

This is the same organisation to which we have just ceded authority in the case of a pandemic.

Click to view the video: https://x.com/its_The_Dr/status/1970302239991316594s

The Multi-Billion Dollar Deception That Turned Our Most Vital Molecule Into Public Enemy #1

What if everything you’ve been told about cholesterol is not just wrong, but deliberately inverted? What if the very substance demonized by a trillion-dollar pharmaceutical empire is actually essential for your survival—and lowering it is slowly destroying your brain, immune system, and will to live?

For over five decades, we’ve been sold the greatest medical lie in human history. The cholesterol hypothesis—the idea that dietary cholesterol and blood cholesterol are the primary cause of heart disease—has generated over $200 billion in statin sales while systematically poisoning an entire generation.

Read the article: https://sayerji.substack.com/p/the-cholesterol-conspiracy-how-big

Peter A. McCullough, MD, MPH

Sep 23

By Peter A. McCullough, MD, MPH

Please enjoy this full length keynote address by Dr. Peter McCullough at the annual meeting of the Association of American Physicians and Surgeons held in Washington DC on September 14, 2025. The outline of this Chautauqua style presentation is divided into three sections:

I. The first great cocaine epidemic 1860-1920

II. Smokefest 1920-1978

III. Vaccine mania 1986-present

In each example the crisis lasts for decades. Doctors participate in the harmful behaviour or procedure and do not self-correct. It takes many years of heterodox heroes calling out the problem, public outcry, court cases, congressional testimony, rooting out corruption, and finally the medical orthodoxy and citizenry are brought back to baseline which is being free or in the natural state unencumbered from the iatrogenic harm.

As illustrated in the NYT best seller Vaccines: Mythology, Ideology, and Reality, while vaccine ideology had been growing for three centuries, it was after the 1986 Vaccine Injury Compensation Act that removed product liability from immunizations that there was an explosion of new products and intensification of the vaccine schedule for children for which every state in the country has requirements for school based on vaccination status. Sadly, as Dr McCullough points out, with this development there was been was of allergic and neuropsychiatric diseases linked to excessive vaccination. To make matters worse, the autism epidemic appears to be a central driver of the transgender crisis.

Finish reading: https://open.substack.com/pub/petermcculloughmd/p/three-great-medical-controversies

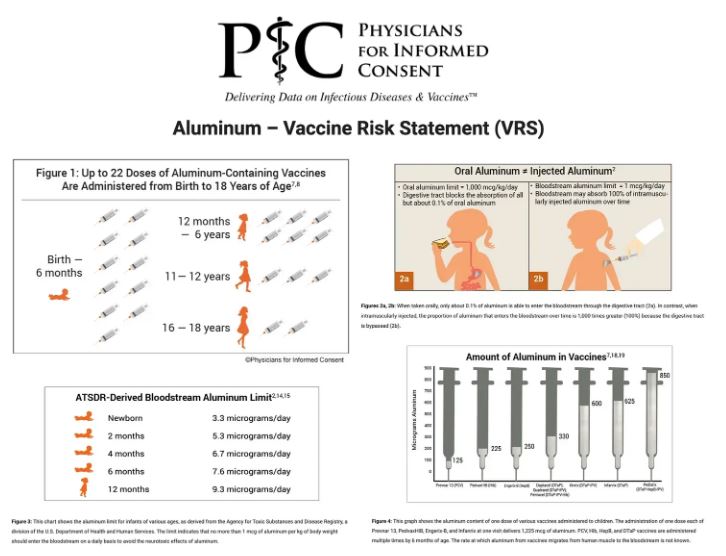

In today’s autism press conference, Trump stated that they will be removing aluminum from vaccines: “We have already taken out and are in the process of taking out mercury and aluminum … You know what aluminum is? Who the hell wants that pumped into a body? … We’re having them taken out of the vaccines.”

Finish reading: https://www.thefocalpoints.com/p/aluminum-removal-from-vaccines-underway

The FDA has issued a nationwide warning about 7-hydroxymitragynine (7-OH), an opioid substance found in some products available in gas stations and convenience stores across the U.S.

7-OH binds strongly to opioid receptors and has been shown to be more potent than morphine, yet it is unregulated, lacks approved medical use, and is often sold without proper safety labeling.

Many 7-OH products are disguised as energy shots or wellness aids, often with bright packaging that looks like candy or juice. This makes them easy to grab, especially for young consumers, and they’re frequently marketed with false claims for pain, anxiety, or mood support.

Most 7-OH products sold in the U.S. are lab-altered or highly processed, delivering doses far beyond what’s found in natural kratom leaves and carrying a much greater risk of dependence and harm.

If you’ve used 7-OH products, tapering gradually, supporting your body with movement, nutrition, and professional guidance helps reduce withdrawal symptoms and support a safe recovery process.

https://articles.mercola.com/sites/articles/archive/2025/09/19/7-hydroxymitragynine-fda-warning.aspx

These five tips are some of the 18 Levers for Optimal Health I have in my book, ‘How To Live The Healthiest Life’.

Watch video: https://www.facebook.com/watch?v=1802600370658789